Integral Fuel Tank

The basic fuel tank setup is similar to Lancair, Velocity & Glasair

The Skins, Spars, & Ribs form the fuel tank

The Common Ring mold is setup for a unique Mid bay Rib, PVC pipe is cut in half and in 90º sections and set in place with molding clay featuring 3/8″ Blend fillets generated by a wide pop cycle stick.

A close in view, the 1st ply to go around the full perimeter has peel ply on each side to protect against release agents and the clay.

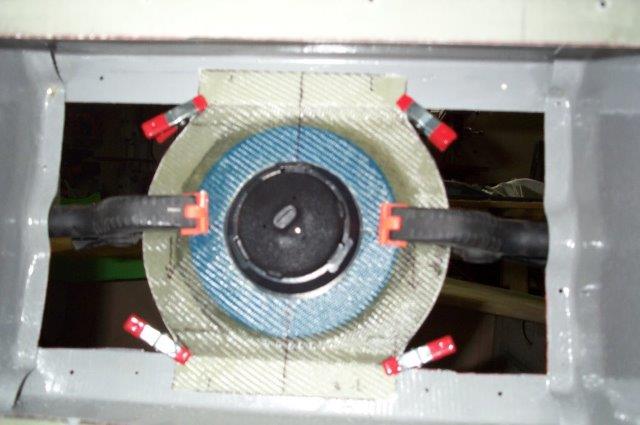

Inboard Mid Bay rib with Blue G10 Hard Points for check valves that allow fuel to come into the inboard collection bay but restrict fuel flow outward

Jeffco 9700 / 3191 Fuel Tank Epoxy coat is used to coat all components in contact with fuel.

On of the benefits of being buddies with several Velocity builders is they only use around half the Jeffco kit,

All ribs with the 1st coat of Jeffco applied (with a roller)

A close in view of the check valves, made from simple extruded piano hinge

Fuel Sender cover / mount plate is attached to the bank most i’m board rib of the fuel bays

Made from .050″ Aluminum

Once the 8 holes are positioned McMaster 3 Hole fixed nut plates are aligned. they do not have a locking feature however they a far more durable than floating MS 21059’s & 61′ the contact area is also higher as well = better for a composite structure

Fuel Tank Sealant will coat the bolts going into the nut plates for the end operation.

A coat of Jeffco over the final installed nut plates

Fit Check on the fuel sender along with the screed fuel pickup, setup is for a 90 ohm system

Although the SP-500’s structure is rated for +/-6 G’s like a Citrabia inverted flight times are limited to a few seconds.

Structurally the wing is symmetric in all load bearing structures.

System test of the fuel sender and gauge using the 12V battery on my truck, everything checks out.

A 1st coat of Jeffco on top & bottom LE skins

Gas Cap Adapter converts from the NACA 63-618 curvature to the flat plate of the fuel cap plate.

Not everything works on the first try, case in point making NACA ducts for the positive pressure pickup. the ridged MDF mold did not want to release the duct (heavily crazed / damaged duct in the middle), so good old Foam Covered in Duct Tape saved the day again, if the finished composite part does not want to release, bust out the Dremel with a foam munching bit in it to take care of business.

Finished NACA Duct install with routed tube.

With most of my Flight time on the Piper Cherokee series I really like the tabs in the tanks that let you know when you hit 17 gals on the money each. I incorporated a similar system on this plane Fuel Level blocks, working the fuel level out for the ground attitude they are set to 1/4 tank ~ 3.25 gal, 1/2 tank ~ 6.50 gal and 3/4 tank ~ 9.75 gal. in terms of time, each block = ~ 40 mins of Cruise power on a O-164 Corvair.